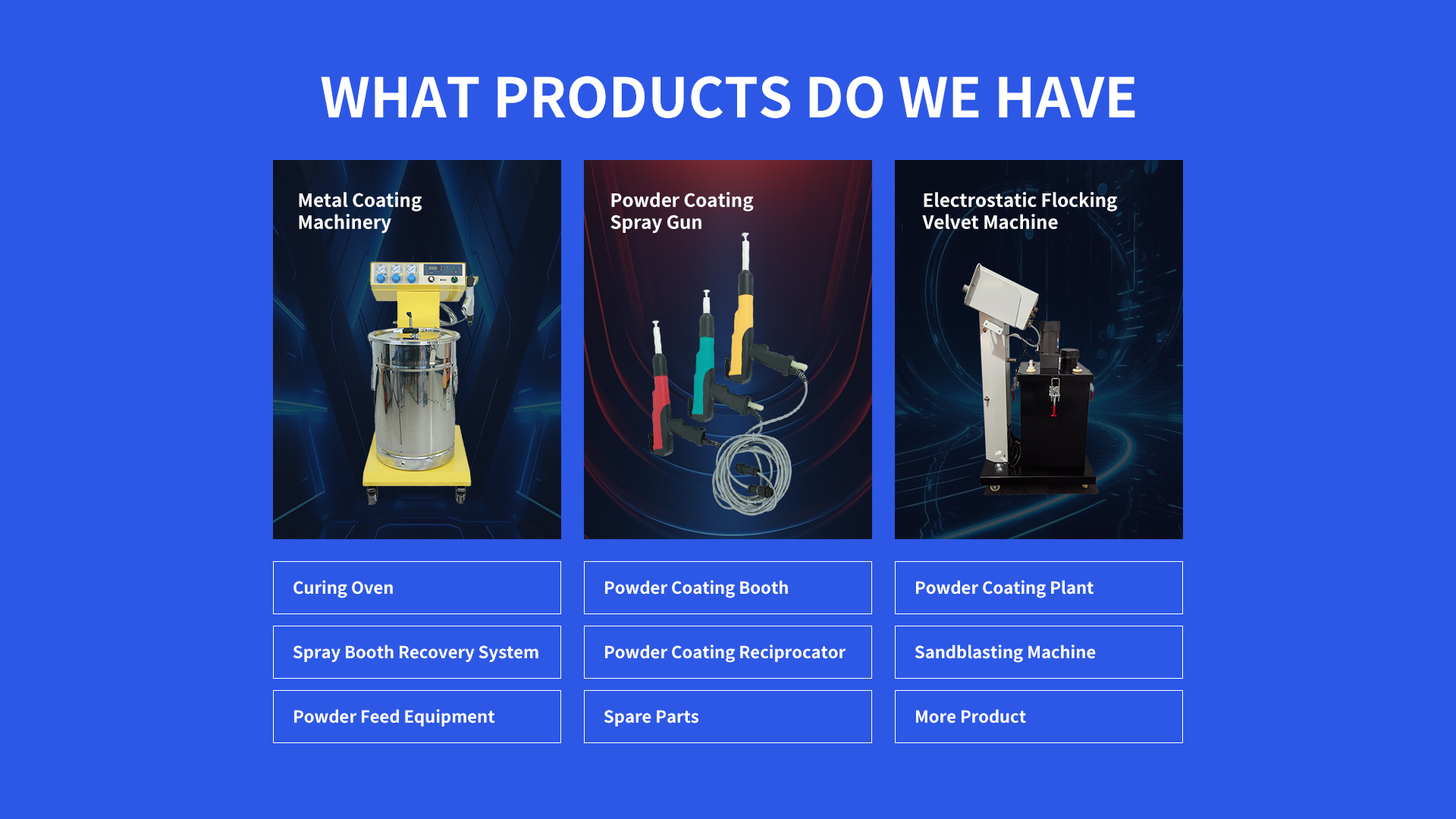

1. Powder Spraying Paint Booth Components and Structure

A Powder Spraying Paint Booth is an enclosed workspace designed to optimize electrostatic powder application. Core components include a steel or aluminum frame, high-efficiency particulate air (HEPA) filters, exhaust fans, electrostatic grounding grids, and lighting systems. Advanced models feature automated conveyor belts, cyclone recovery systems for overspray reuse (95%+ efficiency), and PLC-controlled airflow to maintain consistent negative pressure. Modular designs allow scalability for varying production demands.

2. Applications of Powder Spraying Paint Booths

These booths are critical in automotive manufacturing (body panels, wheels), aerospace (engine components), and appliance industries (refrigerators, ovens). They are also used for architectural metalwork (window frames), furniture (metal fixtures), and agricultural equipment. Specialty applications include coating medical devices with antimicrobial finishes and creating UV-resistant surfaces for outdoor infrastructure.

3. Powder Spraying Paint Booth Price Ranges

Manual booths start at 15,000,whilesemi−automatedsystemsrangefrom50,000–200,000.Fullyautomatedlineswithroboticarmsandcuringovensexceed500,000. Costs depend on booth size (e.g., 5x5x10 ft to 20x20x40 ft), airflow capacity (1,000–10,000 CFM), and features like IoT diagnostics or energy recovery modules.

4. Best Practices for Operating Powder Spraying Paint Booths

Surface Prep: Degrease substrates and apply phosphate conversion coatings.

Airflow Settings: Maintain 0.3–0.5 m/s airflow velocity for minimal overspray.

Gun Technique: Hold the electrostatic gun 8–12 inches from the surface; use overlapping strokes.

Maintenance: Clean filters weekly, inspect grounding systems monthly, and recalibrate sensors annually.

5. How to Choose the Right Powder Spraying Paint Booth

Production Volume: Select batch booths for low volume or conveyor systems for high throughput.

Material Compatibility: Ensure compatibility with epoxy, polyester, or TGIC-free powders.

Safety Certifications: Look for NFPA 33, OSHA, and CE compliance.

Energy Efficiency: Opt for booths with variable-speed fans and heat recovery systems.

6. Safety Measures for Powder Spraying Paint Booths

Ventilation: Use explosion-proof exhaust systems to prevent combustible dust buildup.

Grounding: Ensure all components have <1 ohm resistance to avoid static discharge.

PPE: Mandate respirators (NIOSH N95), anti-static suits, and safety goggles.

Fire Prevention: Install CO2 suppression systems and Class D extinguishers.

7. Design Advantages of Modern Powder Spraying Paint Booths

Advanced booths reduce energy use by 30% via recirculated air systems and heat exchangers. Ergonomic layouts improve operator accessibility, while IoT integration enables real-time monitoring of airflow, temperature, and powder usage. Modular panels allow easy expansion, and stainless steel construction ensures durability in harsh environments.

8. Key FAQs on Powder Spraying Paint Booths

Q: How does a Powder Spraying Paint Booth improve coating quality?

A: Controlled airflow and electrostatic grounding ensure even powder distribution and adhesion.

Q: Can these booths handle large or irregularly shaped parts?

A: Yes, customizable conveyor systems and adjustable nozzles accommodate complex geometries.

Q: What maintenance extends booth lifespan?

A: Regularly replace HEPA filters and inspect electrical components for corrosion.

Q: Are powder spraying booths environmentally friendly?

A: Yes—zero VOC emissions and high overspray recovery reduce waste and pollution.

Q: How to minimize operational costs in powder spraying booths?

A: Use energy-efficient fans, recycle recovered powder, and train staff on optimal gun techniques.

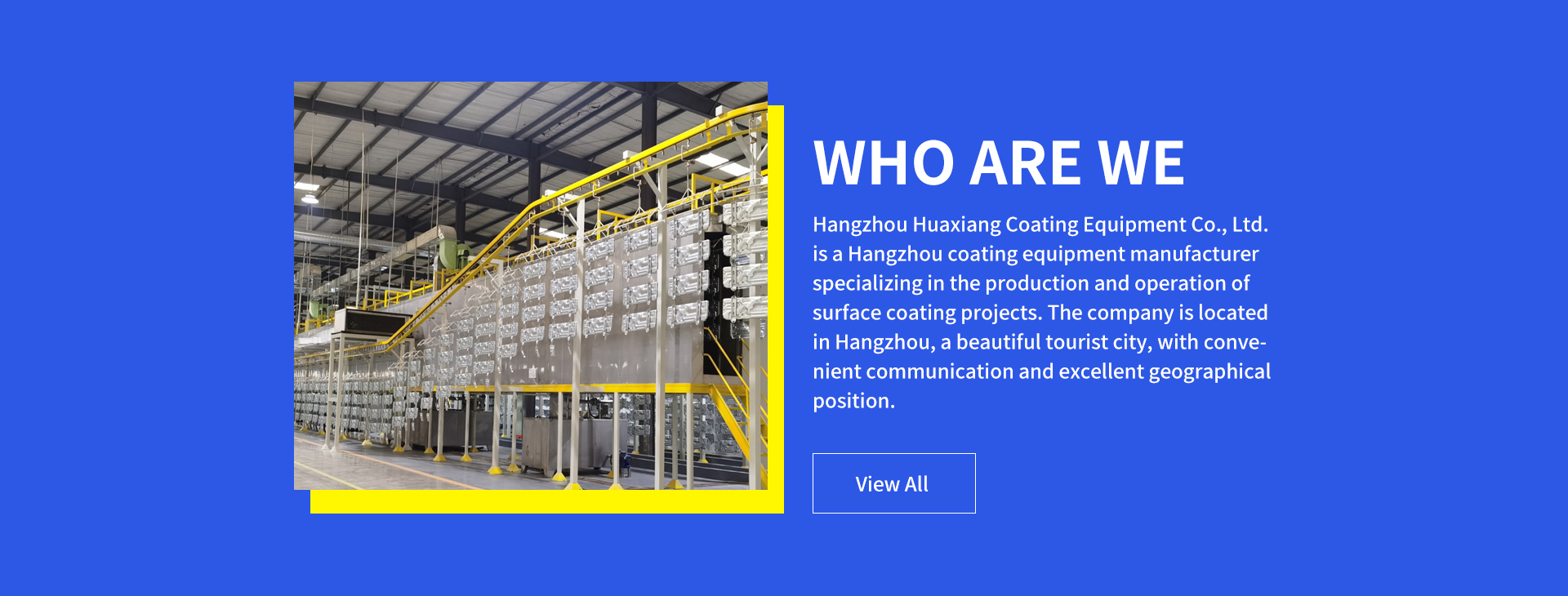

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com